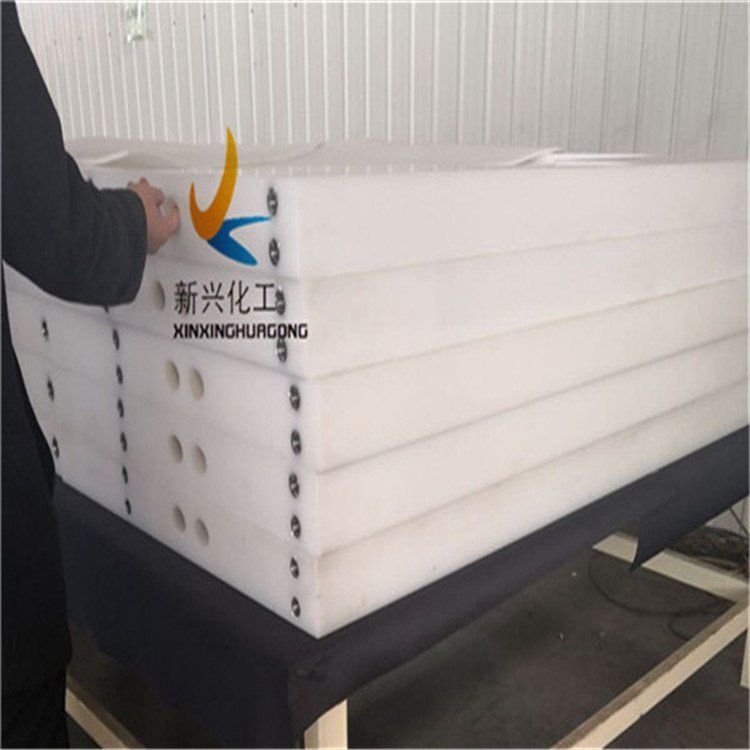

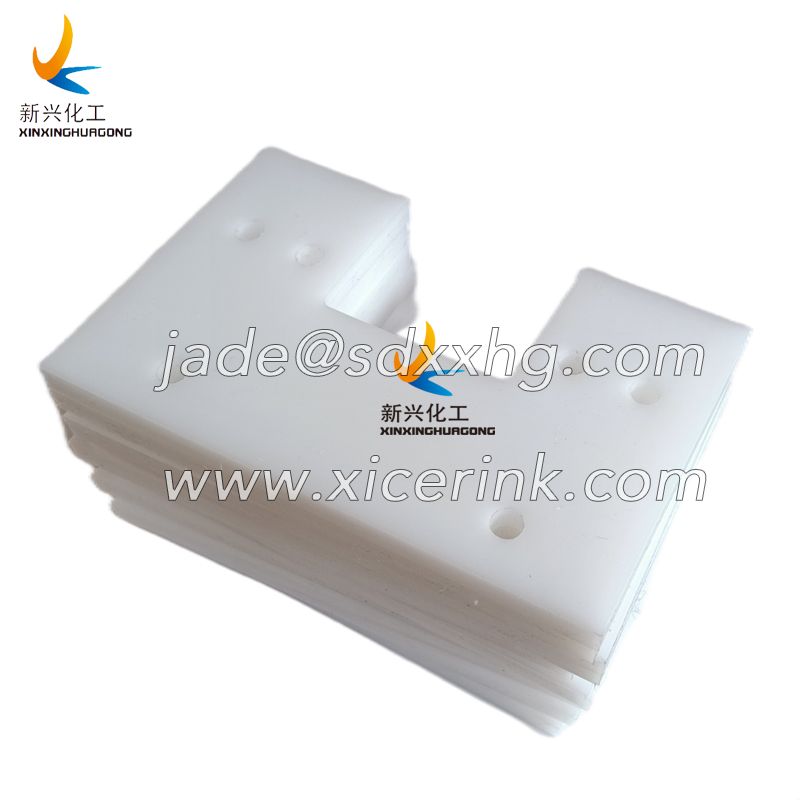

cnc machined uhmwpe wear parts/block/strip

1.Best shock resistance even in low temperature

2.Low frictional factor, and well sliding bearing material

3.Lubricity (no caking, in adhesion)

4.Best chemical corrosion resistance and stress craze resistance

5.Excellent machinery process ability

6.Lowest water absorption

7.Paragon electric insulativity and anti-static behavior

8.Nice high energy radioactive resistanc

9.Abrasive resistance which always have in thermoelectricity polymer

10.Density is lower than other thermoplastic

Product Overview

The properties of UHMW-PE:

Property | Unit | Value | |

Density | g/cm3 | 0.93-0.96 | |

Average molecular weight | g/mol | 3million- 10 million | |

Tensile strength (23°C in air) | MPa | 22 | |

Breaking strength | MPa | 42 | |

Tensile strain at break | % | 600 | |

Charpy impact strength (notched) | mJ/mm2 | No break | |

Ball indentation hardness | N/mm2 | 42 | |

Shore D hardness | -- | 65-70 | |

Abrasion | % | 70-80, steel = 100 | |

Static Friction Coefficient | -- |

≤0.16 | |

Kinetic Friction Coefficient | -- |

≤0.10 | |

Water Absorption | -- | NIL | |

Elongation at break at 23 degress | % | ≥300 | |

Temperature resistance | °C | -269 to +85 | |

Melt Temperature | °C | 130-140 |

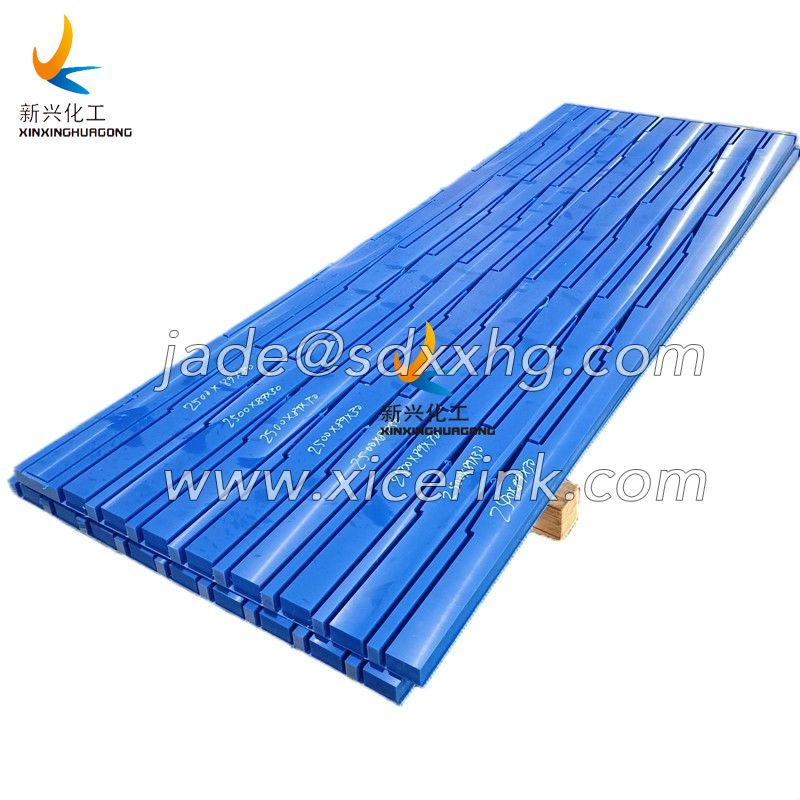

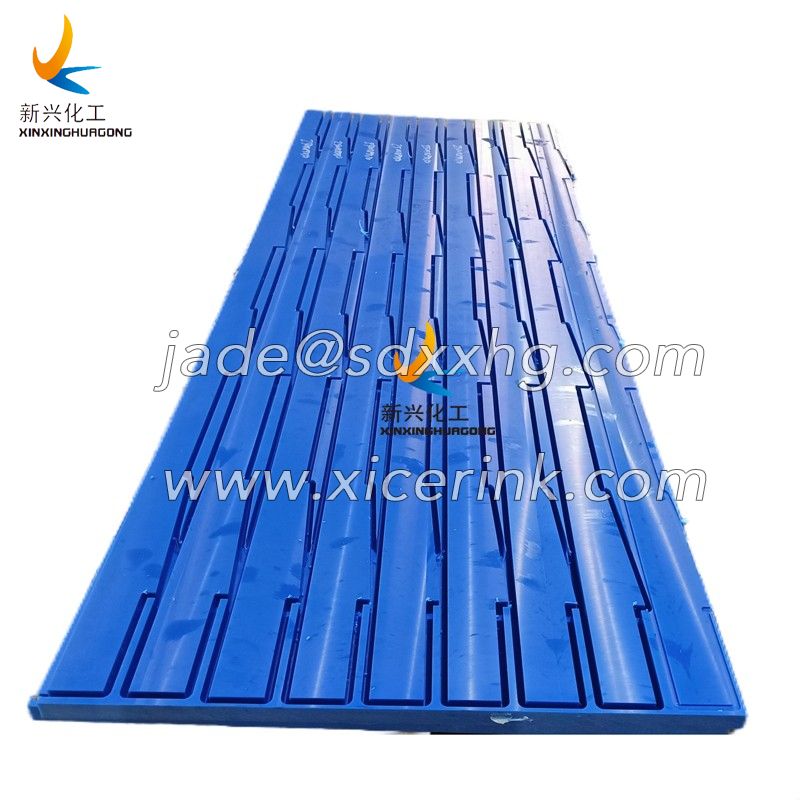

cnc machined uhmwpe wear parts/block/strip APPLICATION

These wear blocks are mounted on the tracks over which the chain travels. Special Antistatic grade of Ultra High Molecular Weight Polyethylene (UHMWPE having antistatic property ensures its suitability for LPG installations, reducing chances of sparks / static current developed because of friction. Various Rectangular, Square, Trapezoidal cross sections, “C” Profile , Special shapes, Curves etc. are available suitable for all installations. Installation of these liners ensures prolonged working of dry chains in dusty atmosphere.

Bottling / Conveying Machinery:

Wear Strips, Machined and Extruded Profiles as Guides, Star Wheels, Timing Screws, Dead Plates and Conveyor Curves. Ideal for use in Breweries, Canning Plants, etc.

Paper Industry:

Suction Box Tops, Forming Boards, Foil Blades, Doctor Blades, Sealing Strips, Deckles and Febriculas.

Mining / Bulk Materials:

Chute Liners, Bin Liners, Truck Liners, Impact Slider Bars, Scraper Blades and Wear Plates

Filter Industry :

Different kinds of filters like Drum Filters, Disc Filters, Belt Filters, etc.

Cold Rolling Industry :

Roll Pads, Roll Racks, Saddle Blocks, Roll Drives & Guide Boards.

Chemical Industry :

Spray Nozzles, Flanges, Impellers, Pump Casings, Filter Plates and Frames, Wear Parts for Belt Filters, etc.

Xinxing attached UHMW-PE pressing mould machine sizes:

1.Thickness: 6 - 300mm

2. Width: max 2000mm

3. Normal standard size:

Length(mm) | Width(mm) | Thickness(mm) |

2000 | 1000 | 6-300 |

3000 | 1500 | 6-300 |

4700 | 1200 | 6-300 |

5000 | 1300 | 6-300 |

4500 | 2000 | 6-300 |

3050 | 1220 | 6-100 |

UHMWPE Machine Parts have the following agvantages:

1.Super high wear resistance

2.Super high impact resistance

3.Super precision

4.Good antistatic property

5.Good chemical corrosion resistance and so on...

Other related products:

UHMWPE Liner (Xinxing-88 UHMWPE Sheet )

Ceramic filled UHMWPE Sheet

Glass filled UHMWPE Sheet

Xinxing is the largest Group manufacturer of engineering plastics in China. Xinxing's main products include UHMWPE & HDPE sheets, double colour HDPE sheets and parts, as well as custom machined plastic parts such as, UHMWPE Synthesis of ice, PE hockey shooting board, plastic ice rink barrier, ICE RINK system, ICE HOKCEY RINK SYSTEM, FLOORBALL RINK, SOCCER REBOUNDER etc. Email: jade@sdxxhg.com

Product Name: cnc machined uhmwpe wear parts/block/strip