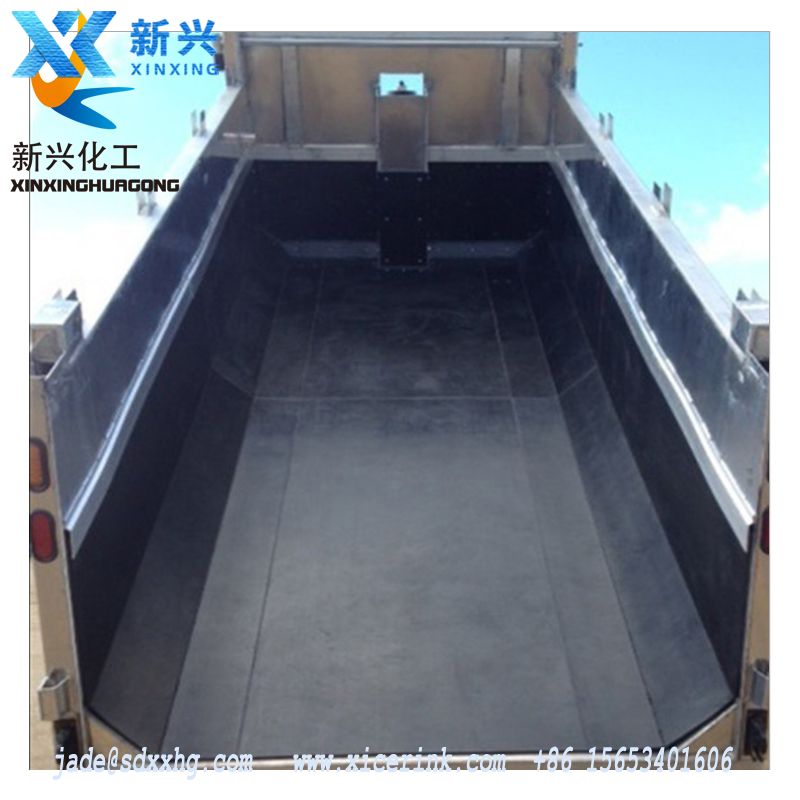

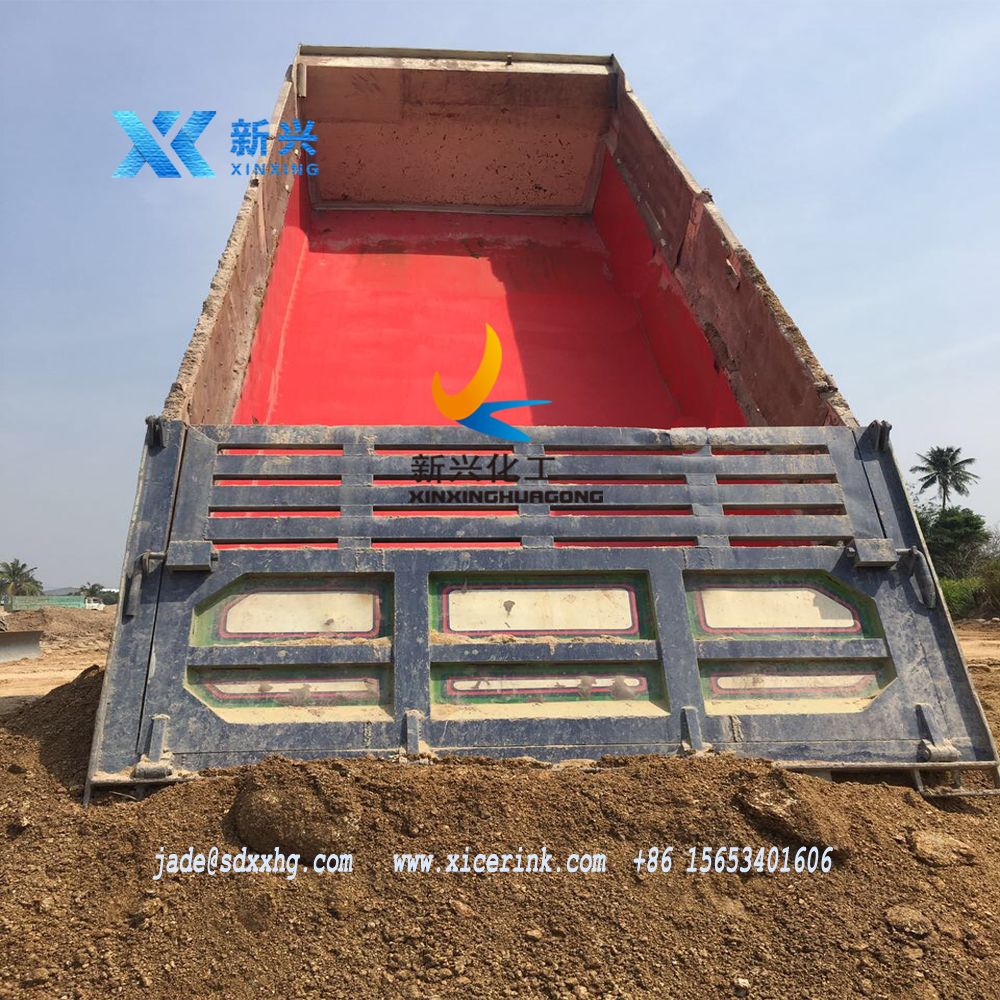

UHMWPE Sheet Wear-Resistant Self-Lubricating Truck/Conveyr Liners

Advantages of UHMWPE truck liners

UHMWPE sheet with continuous length, seamless dump body liners release sticky materials such as clay, coal fly ash or fertilizer in the very best and very worst conditions, eliminating costly flow agents, reducing labor costs and increasing the number of loads hauled each day.

• Provides steady release of bulk materials

• Weighs less than aluminum or steel• Abrasion, corrosion and chemical-resistant

•Economically priced·High impact strength

Product Overview

UHMW-PE Bulk Materials Liner is a high-quality engineering plastic, commonly used in applications for the handling of bulk materials. It provides excellent wear resistance and has a very low friction coefficient which allows materials to flow freely across its surface.

This Solid wear-resistant UHMW-PE material is the best choice for lining chutes, trunks, bunkers, and silos. If properly built PE 1000 / PE-UHMW Liner for Bulk Materials guarantees the maintenance-free functioning and prolongs the operating life of material handling plants.

Different installation methods may be applied for the PE 1000 / PE-UHMW sheets - Bulk Materials Liner as it offers a variety of cost-effective solutions, from simple bolting to rubber backed stick in type liners, space frame construction and even welded drop in liners for manufactured chutes.

PE1000 Bulk Liner is a common alternative for lining chutes, hoppers and silos as it helps solve liquid movement, ratholing, and arching problems. It is solid and stable, exhibits outstanding corrosion resistance and does not absorb moisture. Using in-house CNC machining equipment for fast deployment, our UHMWPE bulk liner is available in a variety of thicknesses and can be machined to order.

Features of UHMWPE Sheets and Components:

Very Low Co-efficient of Friction

High Impact Strength, will not break or shatter

High Abrasion Resistance

Zero Water Absorption.

Chemical Inert, Works with almost all chemical including HCL.

Survive in Freezing Conditions from (-200 Degree C to 80 Degree C)

Anti Sticking Property- Self Lubricated Material

Application Field

1. Lining: Silos, hoppers, wear-resistant plates, brackets, chute like reflux devices, sliding surface, roller, etc.

2. Food Machinery: Guard rail, star wheels, guide gear, roller wheels, bearing lining tile, etc

3. Paper-making machine: Water lid plate, deflector plate, wiper plate, hydrofoils

4. Chemical Engineering: Corrosion and wear-resistant mechanical parts

5. Other: Agricultural machinery, ship parts, electroplating industry, extreme low temperature mechanical components.

6. Thermal power: coal handling, storage of coal, coal bunker lining

7. Coal processing: sieve plate, filter, U-underground coal chute

8. Grain: food storage or chute lining

9. Concrete: cement raw and finished product silo silo lining

10. Mining: sieve plate, chute linings, wearproof anti-bonding part

11. Some kind of rubber fender panels and front face of rubber fender

12. Other fields include Ice rink, water tank etc.

Curve self lubrication uhmwpe truck bed liner,smooth pe plastic truck bed sheet

| UHMWPE Conveyor machinery lining board | UHMWPE Truck Liner | UHMWPE Bucket Linings | UHMWPE Pipe liners |

|  |  |  |

| UHMWPE Cylinder Liner | UHMWPE Coal bunker liner | UHMWPE Hopper liner |

|

|

|

PE 1000 / PE-UHMW sheets - Bulk Materials Liner

Datasheet PDF file

Mechanical Properties

Properties | Test Method | Unit | Guideline Value |

Yield stress | DIN EN ISO 527 | MPa | 21 |

Elongation at break | DIN EN ISO 527 | % | >200 |

Tensile modulus of elasticity | DIN EN ISO 527 | MPa | 680 |

Notched impact strength | DIN EN ISO 179 | kJ / m2 | no break |

Shore hardness | DIN EN ISO 868 | scale D | 64 |

Thermal Properties

Properties | Test Method | Unit | Guideline Value |

Melting temperature | ISO 11357-3 | °C | 135 |

Thermal conductivity | DIN 52612-1 | W / (m * K) | 0,40 |

Thermal capacity | DIN 52612 | kJ / (kg * K) | 1,90 |

Coefficient of linear thermal expansion | DIN 53752 | 10-6 / K | 150 - 230 |

Service temperature, long term | Average | °C | -250 … 80 |

Service temperature, short term (max.) | Average | °C | 130 |

Vicat softening temperature | DIN EN ISO 306, Vicat B | °C | 79 |

Electrical Properties

Properties | Test Method | Unit | Guideline Value |

Dielectric constant | IEC 60250 | 2,3 | |

Dielectric dissipation factor (106 Hz) | IEC 60250 | 0,0001 | |

Volume resistivity | DIN EN 62631-3-1 | Ω * cm | >1014 |

Surface resistivity | DIN EN 62631-3-2 | Ω | 1012 |

Comparative tracking index | IEC 60112 | 600 | |

Dielectric strength | IEC 60243 | kV / mm | 45 |

Other Properties

Properties | Test Method | Unit | Guideline Value |

Density | DIN EN ISO 1183-1 | g / cm3 | 0,96 |

Water absorption | DIN EN ISO 62 | % | <0,01 |

Flammability (Thickness 3 mm / 6 mm) | UL 94 | HB | |

Molecular weight | - | 106 g/mol | ~ 9 |

Characteristics:

Temperature resistance: -40°C up to +82°C.

The UHMW-PE Bulk liner allows reliable, steady bulk material flow.

Good resistance to abrasion and wear.

The bulk material polyethylene liner from UHMW-PE has excellent corrosion and chemical resistance properties.

this UHMW-PE for bulk liner applications is famous for its low coefficient of friction.

No moisture absorption.

Reduces the risk of arching and changeable material flow.

UHMWPE Truck Liner

UHMWPE Bucket Linings

UHMWPE Pipe liners

UHMWPE Cylinder Liner

UHMWPE Coal bunker liner

UHMWPE Hopper liner

Xinxing other products :

Other related products: UHMWPE Liner (Xinxing-88 UHMWPE Sheet ) Ceramic filled UHMWPE Sheet Glass filled UHMWPE Sheet

we look forward to receiving your any enquiries |

Xinxing is the largest Group manufacturer of engineering plastics in China. Xinxing's main products include UHMWPE & HDPE sheets, double colour HDPE sheets and parts, as well as custom machined plastic parts such as, UHMWPE Synthesis of ice, PE hockey shooting board, plastic ice rink barrier, ICE RINK system, ICE HOKCEY RINK SYSTEM, FLOORBALL RINK, SOCCER REBOUNDER etc. Email: jade@sdxxhg.com

Product Name: UHMWPE Sheet Wear-Resistant Self-Lubricating Truck/Conveyr Liners